The manufacturing industry is changing fast, and AI is playing a big part in this shift. But what does that mean for you as a business leader? How can AI help you improve your operations, cut costs, and boost product quality?

Are you looking to reduce downtime and keep your equipment running smoothly? Want to optimize your supply chain and save on production costs? Or maybe you’re curious about how AI can help you offer more personalized products to your customers?

We’ll cover all of this and more, giving you clear examples of how AI can work for your manufacturing business. At Codewave, we help businesses like yours adopt these technologies, so you can stay ahead in a competitive market.

Let’s get into it and explore how AI can help you take your manufacturing operations to the next level.

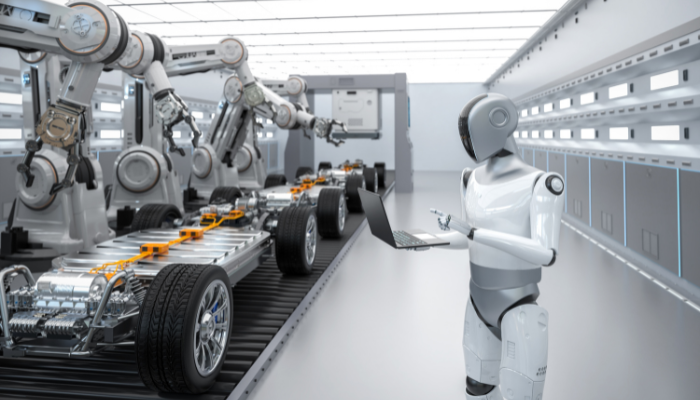

Role of AI in Manufacturing

Artificial Intelligence (AI) is changing the manufacturing industry. It’s not just about new technology, but about making real improvements to how you run your operations, how your team works, and how your products are made. AI brings many benefits that can take your manufacturing processes to the next level.

AI is all about processing and analyzing large sets of data in real-time, something traditional methods can’t do. AI enables the automation of critical tasks like inventory management, quality control, and supply chain optimization. It can also help predict equipment failures by analyzing sensor data in real time, allowing for predictive maintenance that reduces downtime and costly repairs.

Additionally, AI-powered analytics can identify inefficiencies in production lines, highlight areas for energy savings, and offer insights into process improvements that boost overall productivity.

In fact, the global AI in manufacturing market was worth USD 3.8 billion in 2022. It’s expected to grow to around USD 68.36 billion by 2032, with a growth rate of 33.5% each year, according to Precedence Research.

Here’s a closer look at the key benefits AI brings to manufacturing:

Benefits of AI for Manufacturing Businesses

Let’s take a look at how AI benefits manufacturing businesses. From improving efficiency and reducing costs to ensuring better product quality, AI plays a key role in optimizing operations and staying competitive.

1. Efficiency Gains: Streamlining Operations

AI can drastically improve the efficiency of manufacturing processes. Traditional manufacturing systems often rely on fixed schedules and human oversight, which can lead to inefficiencies and bottlenecks. With AI, you can monitor and adjust operations in real-time.

AI can handle complex tasks like:

- Automating repetitive tasks that would normally take up a lot of time for your team.

- Analyzing performance data to identify where delays or inefficiencies are happening.

- Adjusting production processes automatically based on data, ensuring smoother workflows and faster output.

By reducing the reliance on manual interventions, AI ensures that your production lines run faster and with fewer disruptions. The result? More products are made in less time, and your team can focus on higher-value tasks that require human expertise.

2. Better Decision-Making: Data-Driven Insights

The manufacturing world generates vast amounts of data every day, but sorting through it all and using it for effective decision-making can be challenging. AI changes that by turning raw data into valuable insights.

With AI, you can:

- Analyze historical and real-time data to identify trends and make better decisions about inventory, production schedules, and workforce management.

- Spot inefficiencies and areas for improvement, enabling managers to address problems quickly before they grow into bigger issues.

- Make more informed, data-backed decisions that lead to better product designs, production methods, and customer service strategies.

In essence, AI helps you make smarter decisions faster, allowing you to respond quickly to changing market conditions and customer demands.

3. Improved Product Quality: Consistency and Accuracy

Maintaining high product quality is essential for any manufacturer, but it can be a challenge to ensure consistency at scale. AI’s ability to monitor production in real time can improve quality control in ways that traditional methods cannot.

AI helps by:

- Inspecting products during production using computer vision, which can detect even the smallest defects that a human inspector might miss.

- Monitoring the quality of materials and ensuring they meet required standards before they even enter production.

- Ensuring uniformity and precision in the manufacturing process, so each product meets the same high-quality standards.

By reducing human error and ensuring that each product is produced to specification, AI helps you deliver a higher-quality product faster, leading to increased customer satisfaction and fewer returns or rework costs.

Facing challenges in maintaining product quality at scale? Codewave’s AI-powered solutions can help you achieve consistent quality control, reduce defects, and optimize production processes.

[Get in Touch with Codewave Experts]

4. Enhanced Flexibility: Adapting to Market Changes

The manufacturing sector today requires flexibility. Consumer preferences change, new technologies emerge, and market conditions shift. AI helps manufacturers adapt quickly to these changes by providing:

- Agility in production schedules—AI allows production to adjust based on real-time demand, reducing the need for overproduction or stockouts.

- Customization at scale, which is crucial for meeting growing demand for personalized products without disrupting the production process.

By using AI, your manufacturing systems become more responsive to shifts in consumer behavior, helping you stay competitive in a fast-moving market.

Also Read: AI in Hospitality Industry: Redefining Customer Experience

With these benefits in mind, let’s look at some real-world use cases of AI in manufacturing, and explore how businesses like yours can put AI to work for them.

Use Cases of AI in Manufacturing Systems

AI is not just an abstract concept, it’s already making a significant impact across various parts of the manufacturing process. Whether it’s predicting when a machine will break down, ensuring high-quality standards, or optimizing your supply chain, AI is at the core of these advancements.

Let’s dive into the most common use cases of AI in manufacturing and see how these technologies are helping businesses like yours drive efficiency, improve product quality, and save costs.

1. Predictive Maintenance: Preventing Downtime Before It Happens

One of the most significant challenges in manufacturing is unplanned downtime. Every time a machine breaks down unexpectedly, it costs your business time, money, and productivity. But with AI, this doesn’t have to be the case.

How it works: AI-driven predictive maintenance uses data from sensors and equipment to predict when machines are likely to fail. By identifying patterns and anomalies, AI can flag potential issues well before they happen. This allows you to take action, whether that means scheduling maintenance or replacing parts before a failure disrupts production.

Why it matters to you: As a business leader, the last thing you want is a halt in production because of an equipment failure. Predictive maintenance helps you avoid unexpected downtime, reducing repair costs, and keeps your operations running smoothly. This also extends the life of your machinery, helping you avoid costly replacements.

2. Quality Control: Ensuring Consistency and Accuracy

Maintaining high product quality is a priority in manufacturing. But ensuring that every product meets your standards can be challenging, especially when you’re working at scale. AI-powered quality control systems help you achieve consistent product quality, every time.

How it works: AI systems use computer vision and machine learning to inspect products during production. These systems can detect defects, inconsistencies, or flaws in real-time, ensuring that products meet your quality standards before they leave the production line.

Why it matters to you: With AI, you no longer have to rely on manual inspections or spot checks, which can be time-consuming and error-prone. AI improves accuracy and helps catch defects early, reducing the risk of faulty products reaching customers. This leads to higher customer satisfaction, fewer returns, and less waste.

3. Supply Chain Optimization: Smarter Logistics and Inventory Management

Managing your supply chain efficiently is key to keeping costs down and ensuring you meet customer demand. AI is helping manufacturers optimize their supply chains, making them smarter and more responsive to market changes.

How it works: AI analyzes historical data and real-time information to predict demand, optimize inventory levels, and plan better routes for delivery. It also helps manage suppliers and distribution networks, ensuring that materials are available when needed and reducing excess stock.

Why it matters to you: AI can help you avoid stockouts and overproduction, both of which can lead to lost revenue or unnecessary costs. By forecasting demand and optimizing logistics, AI helps you keep your operations lean, reducing storage costs and ensuring timely deliveries. This is critical for staying competitive and meeting customer expectations.

4. AI Chatbots: Simplify Communication and Repetitive Tasks

In the manufacturing industry, the power of AI isn’t limited to physical robots. AI chatbots and intelligent communication systems are increasingly becoming vital tools for automating key tasks and improving efficiency.

How it works: AI chatbots can handle a wide range of functions, from answering routine customer inquiries to managing inventory updates or even providing real-time status reports on production lines. These smart systems work seamlessly across platforms, handling repetitive tasks and ensuring your team stays focused on more complex decision-making.

Why it matters to you: By integrating AI chatbots into your manufacturing processes, you can improve communication speed, reduce manual workload, and respond to customer queries instantly. AI-powered chatbots help your team maintain productivity, streamline operations, and enhance customer experience, all while reducing costs associated with human labor.

Dealing with communication bottlenecks or repetitive inquiries slowing down your team?

[Connect with Codewave]

5. Energy Management: Reducing Consumption and Costs

Energy is one of the largest expenses in manufacturing. Managing energy consumption efficiently is essential for both cutting costs and meeting sustainability goals. AI can play a key role in optimizing energy use across your operations.

How it works: AI systems monitor and analyze energy usage patterns, adjusting equipment and processes to minimize energy waste. These systems can control lighting, heating, cooling, and machinery operation, optimizing energy use without compromising production quality.

Why it matters to you: Not only does AI help you save on energy costs, but it also contributes to sustainability efforts, which is becoming more important to customers and regulators. By reducing energy consumption, you lower operational costs and reduce your carbon footprint, helping you stay aligned with green initiatives and environmental regulations.

6. Digital Twins: Simulating and Optimizing Production Processes

Digital twins are virtual replicas of physical assets or systems. In manufacturing, these digital models are powered by AI to simulate how production systems will behave under different conditions.

How it works: AI-driven digital twins allow you to test and optimize production processes virtually, before implementing changes in the real world. By analyzing the virtual model, AI can predict how changes will impact performance, helping you make better decisions about equipment, processes, and workflows.

Why it matters to you: Digital twins help you avoid costly errors and inefficiencies by allowing you to experiment with different scenarios without disrupting real-world operations. You can optimize processes, test new strategies, and improve your overall production system with minimal risk.

7. Workforce Safety: Protecting Your Team with AI

Keeping your workforce safe is a top priority in manufacturing. AI can enhance workplace safety by identifying potential hazards and alerting workers in real time.

How it works: AI systems can monitor workers’ behavior, detect unsafe practices, and track environmental factors like machine performance, air quality, and equipment conditions. When an issue is detected, AI can alert workers and supervisors to take action before accidents occur.

Why it matters to you: Ensuring a safe working environment reduces the risk of injury, downtime, and legal issues. By using AI to monitor and improve safety, you not only protect your employees but also improve overall productivity and morale.

8. Process Automation: Simplify Operations

AI can automate complex business processes that once required human intervention, making your operations smoother and more efficient.

How it works: AI-powered systems automate tasks like order processing, inventory tracking, and even customer service. By handling repetitive tasks, AI frees up your team to focus on more strategic initiatives that drive growth.

Why it matters to you: Process automation with AI helps you reduce human error, improve efficiency, and speed up operations. This leads to cost savings, higher productivity, and the ability to scale your operations more easily.

Also Read: Use Cases of AI in Analytics

As we’ve explored, AI can significantly improve efficiency, reduce downtime, and enhance product quality. These benefits are not just theoretical, they’re happening right now in manufacturing businesses around the world. But how can you bring these AI-driven improvements to your own operations?

The good news is that integrating AI into your manufacturing systems is more achievable than it might seem. It’s about taking the right steps and having a clear plan.

How to Implement AI in Manufacturing: A Step-by-Step Guide

Integrating AI into your manufacturing processes may seem like a big task, but with the right approach, it can be a seamless and highly rewarding experience. Here’s a simple, step-by-step guide to help you implement AI in your manufacturing systems and start reaping the benefits:

1. Identify Key Areas for AI Integration

Before jumping into AI, take some time to understand your business and identify which areas can benefit most from AI solutions. This could be:

- Predictive maintenance to prevent equipment breakdowns

- Quality control for faster and more accurate defect detection

- Supply chain management to optimize inventory and logistics

- Process automation to improve efficiency and reduce manual labor

Start by evaluating which pain points or inefficiencies in your operations could be addressed by AI. This will help you focus on areas that will deliver the most immediate impact.

2. Collect and Organize Data

AI thrives on data. To make the most out of AI, you’ll need a steady stream of quality data from your machines, sensors, and production lines.

- Gather data: Start by collecting data from existing systems, sensors, machines, and even employees.

- Organize it: Make sure the data is clean, structured, and easy to analyze. Poor data can lead to poor insights, so ensure that your data is organized and ready for use.

If you don’t have the necessary data infrastructure in place yet, it’s time to invest in sensors, IoT devices, and software solutions that can track performance, quality, and machine health in real time.

3. Choose the Right AI Tools and Platforms

Next, you’ll need to choose the right AI tools and platforms to meet your specific needs. There are several types of AI technologies you might use in manufacturing, including:

- Machine learning (ML) for predictive analytics

- Computer vision for quality control and defect detection

- Robotic process automation (RPA) for streamlining repetitive tasks

- Natural language processing (NLP) for managing customer interactions or inventory systems.

Work with experts or consultants to select the AI tools that are best suited for your operations. If you’re not sure where to start, Codewave can guide you in choosing and integrating the right AI solutions for your needs.

4. Train Your AI Models

Once you have your data and tools, the next step is training your AI models. This involves feeding your data into machine learning algorithms to teach them how to identify patterns, predict outcomes, and make decisions.

- Supervised learning: In this method, the model is trained on a labeled dataset where the outcomes are already known. For example, training a model to identify defective products based on labeled images.

- Unsupervised learning: This type of learning allows the model to analyze data without predefined labels and find patterns on its own, such as identifying equipment behavior patterns in predictive maintenance.

Training AI models requires ongoing feedback, so continuously evaluate how well your AI is performing, and make adjustments as necessary.

5. Integrate AI with Existing Systems

AI doesn’t work in isolation. For it to have a real impact, it must be integrated with your existing systems. This may include your enterprise resource planning (ERP) systems, manufacturing execution systems (MES), or supply chain management software.

Integration allows AI to work alongside your current tools, sharing data and improving decision-making across the board. Whether it’s optimizing production schedules or predicting machine failures, AI can become a central part of your operational strategy.

6. Monitor and Fine-Tune AI Systems

Once AI is up and running, it’s essential to monitor its performance regularly. Keep track of:

- Accuracy: Is AI predicting failures correctly, identifying defects, or optimizing supply chain decisions as expected?

- Speed: Is AI processing data and providing insights quickly enough for your team to take action?

- Efficiency: Are AI-driven processes leading to measurable improvements, like less downtime or fewer defects?

AI is not a “set it and forget it” solution. It requires continuous fine-tuning, updates, and learning as new data comes in. Over time, your AI systems will improve, becoming more precise and powerful.

7. Scale AI Across the Business

Once your initial AI implementations are running smoothly, it’s time to expand. Look for other areas of your business where AI can be applied:

- Sales and demand forecasting: Use AI to predict customer demand more accurately and optimize production schedules.

- Customer service: Integrate chatbots or AI-driven customer support systems to handle inquiries and improve customer satisfaction.

- Supply chain forecasting: Scale AI to analyze and predict supply chain disruptions, inventory needs, and delivery schedules.

Scaling AI requires planning and investment, but doing so will multiply the benefits across your entire organization.

8. Train Your Workforce to Use AI

AI can only be effective if your team knows how to use it. Provide training for your employees so they understand how AI is impacting their roles and how they can use AI tools in their day-to-day tasks.

Investing in AI training will help ensure that everyone is on the same page, creating a more cohesive and efficient work environment.

Also Read: Practical AI Use Cases in Major Industries

How to Take the Next Step Towards AI Integration

AI offers immense potential to optimize your manufacturing operations, but how do you make it work for your business? The answer lies in choosing the right partner to guide you through the process.

At Codewave, we specialize in helping manufacturing companies seamlessly integrate AI into their operations. Let’s explore how we can work together to turn these opportunities into real results.

How Codewave Brings AI to Your Manufacturing Business?

Manufacturers often struggle with inefficiencies, unexpected downtime, and slow communication. AI can solve these problems by automating tasks, providing real-time insights, and predicting issues before they happen. This helps improve efficiency, reduce costs, and boost product quality.

1. Customized AI Solutions for Real-World Challenges

Every manufacturing business has its own set of challenges. At Codewave, we focus on tailoring AI solutions that address your specific pain points. Whether it’s enhancing operational efficiency or improving product consistency, we develop custom AI-powered solutions that bring real, measurable impact to your business.

2. Seamless Integration with Your Existing Systems

AI shouldn’t disrupt your existing systems, it should enhance them. We ensure smooth integration with your current ERP systems, MES, and other business tools, so you don’t have to start from scratch. Our approach ensures that AI works alongside your current infrastructure, adding value without causing disruptions.

3. End-to-End AI Development with Expertise

We don’t just build AI, we build the right AI for you. From strategy development and data collection to AI model creation and continuous optimization, Codewave’s team of experts will guide you through every stage of AI adoption. Our expertise in machine learning, computer vision, and predictive analytics ensures that you get high-performing, results-driven solutions.

4. Process Automation for Efficiency and Savings

AI and automation go hand in hand. With AI-driven process automation, we help you eliminate repetitive tasks, optimize workflows, and improve operational efficiency. Whether it’s automating inventory management, supply chain forecasting, or even robotic systems for assembly, Codewave builds automation solutions that are both practical and scalable.

5. AI for Scalable Growth

As your business grows, so should your AI solutions. Codewave builds scalable AI systems that evolve with your business, helping you expand production capacity, optimize new product lines, and adapt to changing market demands. Our solutions are designed to grow with you, ensuring your AI infrastructure supports long-term business success.

With our deep experience in AI/ML development, digital transformation, and IoT integration, we bring practical, innovative solutions to manufacturing businesses. We use advanced technologies, including TensorFlow, PyTorch, and OpenCV, to create AI tools that are specifically designed for manufacturing challenges.

If you’re ready to bring AI into your manufacturing business, we’re here to help.

Codewave is a UX first design thinking & digital transformation services company, designing & engineering innovative mobile apps, cloud, & edge solutions.