Industrial IoT

Industry X.O: A hyperconnected universe

Factory X.O: A hyperconnected universe

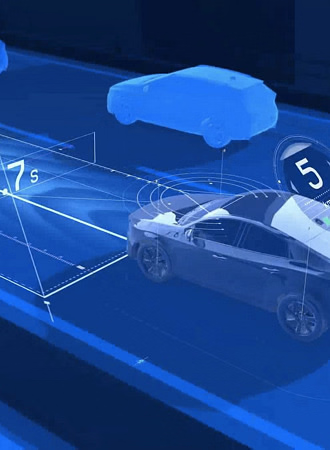

Factories often lose time and money due to breakdowns, lack of communication between machines and lack of integration of devices to systems, and processes. Machines operate in isolation, offering no foresight. What if sensors could track quality in real time or machines could warn you before failing? Industrial IoT turns these “what-ifs” into reality.

We solve these problems using edge computing, digital twins, and AI analytics. Our solutions go beyond connecting devices. We enable predictive maintenance, streamline remote asset tracking, and optimize performance with real-time data. To make this happen, we incorporate platforms like AWS IoT Core, Azure IoT Hub, and MQTT to ensure seamless communication between devices. For spotting anomalies, digital twins allow us to simulate machine behavior, helping prevent costly failures. It’s not just tech—it’s the future of proactive, data-driven solutions.

With Codewave’s IoT expertise, our clients have achieved:

2x

Higher asset performance

99.99%

Asset Availability and uptime

Instant

Anomaly/failure detection

3x

Faster issue resolution

Download The Master Guide For Building Delightful, Sticky Apps In 2025.

Build your app like a PRO. Nail everything from that first lightbulb moment to the first million.

Why you'll love us?

We’re 10x thinkers and change makers, driving extreme-value innovation through human-centric design and emerging tech, defying the traditional.

With a track record of serving 300+ businesses globally, collaborating with VC firms, startups, SMEs, and governments, while also developing our own GenAI products – we’re obsessed with building high-impact products, ready for scale.

Smart sensing tech & constant communication

Asset Tracking

Struggling to track assets? We integrate IoT sensors with Node-RED and TensorFlow to create automated tracking systems.

For example, if a forklift is delayed or a shipment goes off route, you’ll get instant updates to make corrections on the spot. This eliminates manual tracking errors, speeds up operations, and ensures your resources are always where they’re supposed to be.

Machine Monitoring

Downtime can be expensive, and unexpected breakdowns happen in business. IoT sensors and IBM Maximo lets you monitor machines 24/7.

Imagine a system that alerts you when a motor is overheating before it fails. That’s exactly what we deliver. You’ll avoid costly interruptions and extend the life of your equipment by addressing issues early.

Predictive Maintenance

Why waste time and money on scheduled maintenance that isn’t actually required? Azure IoT Hub allows us to predict failures by analyzing performance data.

For instance, if a conveyor belt shows wear beyond safe thresholds, you’ll get an alert to service it before it snaps. This keeps your machines running efficiently while reducing unnecessary repairs and downtime.

Proactive Maintenance

Why wait for something to break? Our IoT sensors, paired with Siemens MindSphere, provide a constant health check on your machines. Think of it as a mechanic keeping tabs on your equipment 24/7.

Get frequent alerts to potential problems instead of waiting for an emergency. With this proactive approach, you’ll keep production steady and avoid unplanned expenses.

Inventory Management

Running out of inventory or sitting on too much? RFID tags and SAP Leonardo lead to track stock levels in real time. For example, if your warehouse is running low on key parts, our system alerts you so you can reorder on time.

Additionally, use AI to predict future inventory needs based on seasonal trends, helping you maintain just the right balance—nothing more, nothing less.

Supply Chain Management

A single delay can throw your entire supply chain into chaos. IoT-powered systems, like SAP S/4HANA, provide real-time shipment updates.

For instance, if a truck is stuck in traffic, you’ll know immediately and can reroute other deliveries. This transparency helps you prevent delays, reduce costs, and ensure everything moves smoothly.

Automated Industrial Processes

Manual processes create opportunity for error and inefficiency. We automate industrial workflows using tools like Node-RED for process adjustments and TensorFlow for predictive controls.

It works for a production line that adjusts its speed automatically to meet demand fluctuations. With automation in place, you’ll boost productivity, eliminate costly errors, and save time.

Smart Data Analytics

Decision-making gets tricky when you’re working with outdated numbers. Apache Kafka and Power BI work best to deliver live, actionable insights.

For example, you can track energy usage in real time and reduce consumption during low-demand periods. By analyzing trends and forecasting needs, we empower you to make better decisions, faster.

Edge Computing

Lack of decisiveness and timely decisions can slow down your business growth, especially in remote areas. Codewave’s edge computing solutions, powered by AWS Greengrass and Microsoft Azure IoT Edge, process data directly at the source.

Imagine monitoring a wind turbine in a remote area and getting instant alerts about performance drops. This local processing minimizes delays and keeps operations running efficiently, even in low-connectivity zones.

Remote Monitoring

When your infrastructure is spread out over large areas, staying on top of performance becomes a challenge. We use IoT sensors with Google Cloud IoT and AWS IoT Core to monitor systems remotely.

For example, if a power grid experiences voltage fluctuations, you’ll be notified immediately. This early detection helps you resolve issues before they cause major disruptions, ensuring reliability and uptime.

Why Codewave, for IoT development?

Data

We devise a Data-AI strategy that gives you a competitive edge.

Actionability

Our data analytics solutions give you actionable insights.

Analytics

We set up tools to give your business actionable insights.

3S of Tech

Our app development ensures speed, security and scale.

Releases

We do rapid, secure releases (minus the drama).

Agility

We architect apps for maximum flexibility & resilience.

Scalability

We ensure your server automatically scales up/down based on usage.

Seamless UX

We create ‘integrated user experiences’ across devices.

We take you from where you are to where you want to be.

Every business has unique IoT needs. Custom Industrial IoT applications are built using React Native and Flutter for scalability and daily reliability.

With offline-first architecture and a microservices backend, your app runs smoothly even when connectivity is lost, adapting seamlessly to your business demands.

Security is embedded into every solution, from biometric access to encryption protocols.

For remote monitoring, blockchain technology ensures tamper-proof data, keeping your devices and information secure while your business scales.

Automation powered by AI and machine learning enhances IoT systems, like predicting equipment failures before they happen, minimizing downtime.

AI-driven systems also adapt to user preferences in real-time, making informed decisions that keep your business agile and efficient.

What Codewave’s IoT Services Can Do for You?

We approach Industrial IoT with a clear purpose: to create real, measurable impact for your business. Operations are streamlined, reducing downtime, and enabling smarter decisions through holistic insights.

Real IoT value comes from a strategy, not just devices. By analyzing your processes, gaps like data silos and manual inefficiencies are identified.

For instance, IoT sensors can detect early equipment failures, allowing your team to act before breakdowns occur. We ensure your IoT system addresses real needs and delivers measurable results.

Raw IoT data becomes valuable through tools like D3.js and Chart.js. Tracking equipment performance, for example, allows machine learning to predict failures, enabling proactive maintenance and reducing downtime. This leads to faster, smarter decisions that push the business forward.

Custom dashboards built with React and Vue.js offer real-time monitoring, whether tracking production lines or energy usage.

These dashboards integrate with existing systems, providing an intuitive interface accessible on any device to ensure fast decision-making, anywhere.

What to expect working with us.

Recommended Tech Stack for IoT Projects

Our toolkit is built to handle real-world IoT challenges, from seamless data flow to precise sensor integration and secure connectivity. At every layer, we ensure you have the flexibility and power to scale.

Category | Technology |

| Languages | JavaScript (Node.js, React), Python, Swift (iOS), Kotlin (Android) |

| Frameworks | React Native, Flutter, Angular, IoT.js |

| Platforms | AWS IoT, Microsoft Azure IoT Hub, Google Cloud IoT Core, IBM Watson IoT |

| Protocols | MQTT, CoAP, HTTP/HTTPS, WebSockets |

| Hardware | Arduino, Raspberry Pi, NVIDIA Jetson, ESP32/ESP8266 |

| Sensors | Temperature sensors, Proximity sensors, Accelerometers, Humidity sensors |

| Connectivity | Wi-Fi, Bluetooth Low Energy (BLE), Zigbee, LoRaWAN |

Transforming Industries with IoT Solutions

We helped a manufacturing client reduce downtime by implementing predictive maintenance. With over 400 global clients, we deliver innovative solutions that make your systems smarter and more efficient.

Our custom solutions tackle specific challenges in your industry, whether it’s optimizing supply chains or enhancing equipment reliability.

Industry | Usecase |

| |

| |

| |

| |

| |

| |

|

Frequently asked questions

Industrial IoT (IIoT) connects sensors, instruments, and devices within industrial setups like manufacturing and energy management. It enables companies to collect, share, and analyze data from physical assets, improving operational efficiency, anticipating maintenance, and fostering innovation in industrial processes.

An IIoT system typically consists of sensors, connected devices, communication networks, cloud platforms for data storage and analysis, and applications that interpret the data to enable informed decision-making.

IIoT offers multiple benefits for your business:

- Boosts operational efficiency through real-time monitoring

- Reduces downtime with predictive maintenance

- Enhances safety and compliance with automated alerts

- Provides data-driven insights for smarter decisions

- Opens up new revenue opportunities with innovative offerings

- Saves costs by optimizing resource and energy usage

IIoT enhances operational efficiency by enabling real-time monitoring, predictive maintenance, and automated control systems, reducing downtime, minimizing resource waste, and improving performance across industrial processes.

By collecting real-time data from machines and sensors, IIoT systems can analyze performance patterns, predict potential failures, and alert teams ahead of time, enabling proactive maintenance and reducing unplanned downtime.

Codewave’s IIoT approach stands out with:

- Design Thinking-led innovation for user-centered solutions

- Global expertise and local support in multiple regions

- Cross-platform development for versatile applications

- A UX-first “Delight by Design” philosophy ensuring intuitive interfaces

Comprehensive services from strategy to implementation and support – our approach ensures your IIoT solution is both technologically robust and aligned with your business goals.

Codewave’s IIoT solutions suit a variety of industries, including:

- Manufacturing

- Energy and Utilities

- Transportation and Logistics

- Agriculture

- Healthcare

- Smart Cities

With experience across sectors, we apply best practices to solve industry-specific challenges with innovative solutions.

Security is a top priority in our IIoT solutions. We ensure protection through:

- End-to-end encryption for safe data transfer

- Secure device authentication and authorization

- Regular security audits and updates

- Compliance with industry-specific security standards

- Edge computing for secure, on-device data processing

Robust access control and user management

Our team stays updated on the latest security threats and best practices, ensuring your IIoT infrastructure is always protected.

Our IIoT implementation process includes:

- Initial consultation and requirements gathering

- Design Thinking workshops to identify challenges and opportunities

- Strategy development and solution architecture design

- Prototyping and iterative development

- Integration with existing systems and infrastructure

- Testing and quality assurance

- Deployment and user training

- Ongoing support and optimization

- Common platforms include AWS IoT Core, Microsoft Azure IoT Hub, Google Cloud IoT, and IBM Watson IoT. These platforms provide the necessary tools for device management, data analysis, and application development.

Yes, IIoT can be integrated with legacy systems through APIs, gateways, and middleware, allowing you to enhance your existing infrastructure with IoT-enabled capabilities without a full system overhaul.

Common sensors in IIoT include temperature sensors, pressure sensors, humidity sensors, motion detectors, and vibration sensors, which collect critical data for monitoring machine health, environmental conditions, and process performance.

IIoT helps optimize energy usage by providing real-time monitoring and insights into energy consumption, enabling predictive maintenance of energy equipment and identifying opportunities to reduce energy waste.

Cloud computing in IIoT enables centralized data storage, scalable processing power, and real-time data analytics. It allows businesses to access their IIoT data and insights remotely, facilitating better decision-making.

By integrating IIoT solutions, businesses can track assets, monitor inventory in real-time, and optimize logistics, ensuring a more efficient and transparent supply chain process.

AI and machine learning play a key role in analyzing large sets of IIoT data. These technologies can predict trends, detect anomalies, and automate processes, improving the accuracy and efficiency of decision-making.

IIoT enhances safety by enabling real-time monitoring of hazardous conditions (e.g., gas leaks, temperature spikes) and providing alerts to prevent accidents, ensuring compliance with safety standards and protecting workers.

The ROI from IIoT can include reduced operational costs, minimized downtime, improved asset utilization, optimized resource allocation, and increased production efficiency, leading to both cost savings and revenue growth.

Betting on the next big idea?

Betting on the next big idea?

Know what will fly & what won’t.

Let’s do design thinking

Most in demand

Comprehensive Software Consulting Services

IT Architecture Services for Enterprises

Cloud Software Solutions

Automated Invoice Processing Cloud Service Solutions

Comprehensive Backend Development Services and Solutions

LMS Development Services for Modern Learning Needs

Database Migration Service for Enterprises

AI OCR Solutions for Accurate Document Processing

Enterprise Blockchain Development Services

Cross-Platform Mobile App Development Services

Custom Enterprise Application Development Services

Custom E-Commerce Solutions for Enterprises

Travel Technology Solutions and Services Management

Global Design and Innovation Consulting Services

LLM in Corporate Compliance and Risk Management

Services in Software Development

Travel Technology Solutions and Services

Generative AI Consulting and Strategy for Business Innovation

Application Operations and Management Services

Secure, Reliable Cloud Application Modernization Services

Global Design and Innovation Consulting Services

Enterprise Cloud Consulting & Implementation Services Solutions

Ecommerce Web Design & Development Services

Trusted, Unified Xamarin App Development Services You Need

Custom EHR/EMR Integration Services for Connected Healthcare

Cyber Security Consulting Services for Scalable Resilience

AI and Data Analytics Services Solutions

Enterprise App Development Services

Business Intelligence and Data Analytics Solutions

Convert Your Website into a Mobile App for Android and iOS

Managed Healthcare IT Services and Solutions

Custom .NET Software Development Services & Solutions

Website Design and SEO for Medical Practices and Doctors

Big Data Analytics Solutions & Services

IOT Product Development Services for Faster Decision Making

Cloud-Based E-commerce Solutions and Platforms

Custom Financial Software Development Solutions

Enterprise Automation Solutions and Services

Power Up Digital Change with Strategic Design Thinking Workshops

Design Thinking-Driven Strategic Digital Transformation Blueprint

Generative AI Development Platform

Information Technology Strategy and Consulting Services

Product Design and Development Services

Custom Responsive Web Design Services

Magento eCommerce Development and Design Services

Transportation and Logistics IT Services and Solutions

Decision Intelligence Strategy

Automation for Operational Efficiency

Digital Talent Transformation

Integrated CX And UX Design For Delight

Digital Transformation ROI Measurement

Digital Core Modernization

Cloud Migration Services

AI Accounting Software

Software Product Development Services

Decentralized Finance (DeFi) Development Solutions and Services

Startup Software Development Services

Django Development Company for Scalable Web Solutions

HIPAA Compliance and Advisory Services Solutions

Drupal Development Services

Business Analytics Services

Telemedicine Software Development Services

Support and Maintenance Services for Mobile and Web Applications

Cryptocurrency Development Services and Solutions

AI Testing Services / AI-Powered Testing Services

IT Infrastructure Services

ASP.Net Software Development Services

Retail IT Solutions and Services

Managed Application Services

Data Warehouse Services

Data Science Consulting

Agentic AI Product Design And Development Services

Healthcare Mobile App Development Services

CRM Consulting and Implementation Services

Custom Database Development Services and Solutions

Transportation and Logistics Software Development Solutions

Secure Payment Gateway Integration Solutions

Data Management Services

Java Software Development Services

PHP Development Services

Fast, Scalable, Secure Node.js App Development

Power BI Consulting Services

IT Project Management Services

NFT Token Development Services

DevOps Consulting and Services

Web Data Mining Services

Front-End Development Services

Managed Services for E-commerce Success

Website Redesign Services for Strengthening Your Web Presence

Custom SaaS Development Services

Custom CMS Web Development Services

NFT Marketplace Development Services

Smart Contract Development Services

Oil and gas IT services

AI Audit for Startup Companies | Best Website Audits

PrivateGPT Development Services

Swift iOS App Development Services

Web3 Development Services Company

AI-Native Product Design and Development Services

Personalized Learning with AI for Education

Microsoft Dynamics 365 Customer Service with AI

Energy Management Software Solutions Platform

Human Machine Interface Software Development Service

Education Software Development Services

Retail Software Development Services and Solutions

DEX – Digital Employee Experience Software Services

Decentralized Exchange Development (DEX) Company

Offshore Software Testing Services

Backend Development Services and Solutions

Travel and Hospitality Software Development Services

Fintech Software Development Services

Data Visualization Consulting Services

Digital Solutions For Agriculture and Software Services

Payment Gateway and Software Development Services

B2B Travel Software and Booking

MEAN Stack Development Services

24/7 Managed NOC Services

Database Migration Service

Design-Led AI Consulting for SMEs and Startups

AI Solutions Development Services

P&C Insurance Software Solutions

MLOps Consulting Services

Generative AI Services and Solutions

Conversational AI Platform Development

AI and Analytics for Retail Solutions

Artificial Intelligence Video Chatbot Services

Digital-First Banking IT Services

Golang Development Services

MVP Development Services

eLearning Software Development

Agile Software Development Services

Data Warehouse Consulting and Management Services

IT Services Management Consultancy Services

Learning Management System Consulting Services

iOS App Development Services Company

Ecommerce Services

Marketing Automation and CRM Solutions

Industrial IoT Solutions and Services

Healthcare Data Analytics Solutions

Cryptocurrency Wallet Development

Digital Strategy Consulting Services

B2B Portal Development

Embedded Technology Innovation

Process Automation

XR Application Development

Artificial Intelligence and Machine Learning Consulting Services

Cloud Infrastructure

Blockchain Implementation

Flutter App Development

Angular Development

Mobile Application Testing Tools and Services

Penetration & Vulnerability Testing

QA Testing Services

Reactjs Development

Team Augmentation

Automation Testing

Web App / Portal Development

Python Development

IT Consulting

Custom Software Development

Branding

ReactNative App Development

Web and Mobile App UX – UI Design Services

UX & UI Design

Android App Development

Mobile App Development

Idea to Product

IoT Development

Data Analytics Development

GenAI Development

AI/ML Development

Design thinking

Process Automation

Digital Transformation

Customer Experience Design