Logistics software development

Transportation software development

Transportation and Logistics Software Development Solutions

Precision Software For Logistics

Missed deliveries, wrong ETAs, and stock mismatches don’t just slow you down—they negatively impact revenue, profit, and customer trust. You need precision logistics software that delivers real-time tracking, auto scales with demand, and unifies your supply chain for maximum performance.

We build logistics software that brings complete visibility and control to your operations. Our AI-driven route optimization minimizes delays, real-time GPS tracking ensures accurate ETAs, and IoT sensors monitor cargo conditions in transit. Automated inventory management syncs with demand forecasting, so you’re never overstocked or out of stock. With cloud-based architecture, every part of your supply chain—warehousing, transportation, and last-mile delivery—operates in sync.

Our solutions fit into your existing ERP, WMS, and TMS systems without disrupting daily operations. AI-powered dashboards deliver real-time insights, helping you prevent issues before they escalate. Scalable and future-ready, our software supports long-term efficiency.

With our logistics software development, you achieve smarter, faster operations.

> 95%

On-Time Delivery Rate

20%

Lower Order Cycle Time (Time To Delivery)

98-99%

High Fill Rate (Fulfillment from Stock)

Download The Master Guide For Building Delightful, Sticky Apps In 2025.

Build your app like a PRO. Nail everything from that first lightbulb moment to the first million.

Delayed Deliveries And The Drama - Here is Your Fix

We build logistics software that cuts delivery costs by 25% and boosts fleet use by 30%. With real-time tracking, smart routing, and full system control, we turn bottlenecks into opportunities for smooth, scalable operations.

We develop custom logistics software that connects directly to your ERP, WMS, and TMS, automating tasks like dispatch, inventory tracking, and document flow.

Using REST APIs, we ensure seamless communication between systems, while RabbitMQ queues manage high-volume events efficiently. We also utilize cron-based job schedulers to automate tasks like invoicing and inventory updates, ensuring everything stays synced and up-to-date without any manual input.

For example – as soon as a shipment arrives, it is automatically scanned using RFID readers. Instantly, your software updates stock levels, matches items to purchase orders, and auto-generates invoices—no manual input, no delays. The next step in your workflow is automatically triggered; keeping inventory, billing, and fulfillment in perfect sync. It’s fast, accurate, and fully automated—so your team moves quicker, errors are eliminated, and customers stay happy.

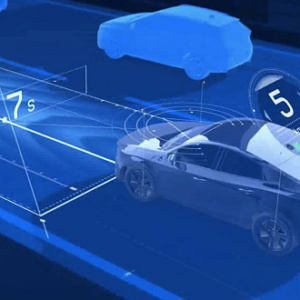

Your TMS needs to do more than just track trucks—it should optimize every aspect of your transportation network. We create TMS solutions that use graph-based algorithms to plan fuel-efficient routes, dynamically reroute shipments based on weather, traffic, or road closures, and automatically select the most reliable carriers based on real-time data.

Using carrier APIs, we pull in rate data from multiple carriers, allowing the system to select the best shipping partner without manual intervention. Meanwhile, GPS and IoT sensors monitor fleet health in real-time, providing live updates on things like tire pressure, fuel usage, and engine performance. This means you can anticipate issues before they arise and make smarter decisions on the fly.

For example, let’s say a traffic jam causes a delay on one of your routes. Your TMS will automatically adjust the route to avoid it, updating the driver and your dispatch team, while customers receive real-time notifications with the new delivery estimates. This eliminates manual rerouting and improves on-time delivery, all while reducing fuel costs.

Efficient warehouse operations are crucial to getting products out the door on time. We build WMS platforms that give you real-time visibility into your warehouse, from stock levels and bin locations to order statuses. By integrating RFID tags and barcode scanners (such as those from Zebra and Honeywell), we automate item scanning, ensuring that everything is tracked with precision.

We also use task allocation engines to automatically assign pick-and-pack tasks based on proximity, load, and warehouse layout, which minimizes idle time and optimizes worker productivity. Our systems integrate seamlessly with conveyor belts and automated storage units, creating a synchronized, fully connected warehouse environment.

For example, when a new shipment arrives, it is scanned and the system automatically updates inventory levels, generates a picklist, and assigns tasks to workers. Workers can see what items need to be picked, in what order, and where they are located in the warehouse—all from a simple, real-time dashboard. No more searching through aisles for items or performing manual stock checks.

We know that managing a fleet requires more than just tracking locations. Our fleet management software provides real-time updates on fleet health, driver behavior, and vehicle performance, helping you stay ahead of issues before they disrupt your operations. We integrate Google Maps API for accurate GPS tracking and combine it with OBD (On-Board Diagnostics) systems to monitor things like engine performance, tire pressure, and fuel consumption.

We also use predictive analytics powered by Azure Machine Learning to predict when maintenance is due, so you can schedule repairs before they become a costly issue. Our system also tracks driver behavior, flagging things like harsh braking, speeding, and excessive idling, which can help reduce accidents and improve fuel efficiency.

For example, your fleet manager can use the dashboard to check the health of each vehicle in real-time, receiving alerts for issues like low tyre pressure or upcoming maintenance needs. This proactive approach ensures your fleet runs smoothly without unexpected downtime, while also helping you manage driver safety and fuel efficiency more effectively.

We build SCM platforms that offer full visibility across your supply chain, from sourcing to delivery. Our solutions integrate demand forecasting models using tools like TensorFlow for predictive analytics and Power BI for visualizing historical sales, seasonal patterns, and inventory trends—optimizing procurement cycles.

We also integrate supplier portals that enable seamless collaboration with your suppliers. These portals allow for real-time order tracking, automatic purchase order generation, and data sharing, so you can stay ahead of any supply chain disruptions. With workflow automation powered by Apache Airflow, we can quickly flag delays, shortages, or disruptions, and offer recommendations on how to resolve them.

For example, your software automatically senses demand and adjusts inventory levels based on forecasted demand, and when stock levels dip below a certain threshold, an automated order is placed with the supplier. This ensures that production continues without interruption, and manual tracking is kept to a minimum.

Your orders move faster with our intelligent OMS solutions. We automate the full lifecycle—from order intake to fulfillment—using rule-based routing, inventory sync, and real-time status updates across channels. Tools like Apache Kafka enable real-time order event streaming, while PostgreSQL ensures consistent inventory state across warehouses.

Additionally, our returns and refunds module automatically processes returns and initiates workflows for customer refunds, using barcode scanning to identify returned items and update inventory levels in real time.

For example, as soon as an order is placed, the system routes it to the nearest warehouse, checks the stock, and automatically adjusts inventory across all locations. If a customer needs to return an item, the system processes the return and updates stock and financial records automatically.

We build dispatch and delivery management software that optimizes your last-mile delivery process. Using the Mapbox Navigation SDK, we provide real-time route optimization and delivery tracking. Our system uses Firebase Realtime Database to instantly sync task updates between dispatchers and drivers, ensuring everyone stays on the same page.

With geo-fencing features, the system automatically updates the status of deliveries—whether the driver is “on the way,” “arrived,” or “delivered”—without manual input, improving delivery accuracy and customer satisfaction.

For example, when a driver reaches the delivery location, the system automatically updates the delivery status and sends a confirmation to the customer, eliminating manual updates and speeding up the overall delivery process.

Your logistics data should be a powerful tool for making decisions. We build custom logistics dashboards that give you real-time insights into performance across your entire supply chain, from warehousing and delivery to fleet management. Using Power BI, we visualize key metrics like route efficiency, order cycle time, and driver performance, while Apache Kafka handles live data streaming for real-time monitoring.

Our system also includes automated alerts for things like late dispatches, SLA breaches, or high return rates, so you can take action before small issues escalate into major problems. Reports are automatically generated and can be sent to the relevant stakeholders through email, Slack, or downloaded as Excel or PDF files.

For example, the system tracks deliveries across different regions and highlights areas where delays are most common. It automatically adjusts dispatch planning to avoid these bottlenecks, cutting down on operational costs and improving delivery times.

Stay In Control Of Your Logistics Operations

We build for real-time control, faster deliveries, and fewer errors, so your supply chain runs exactly how you need it to.

Your logistics network becomes smarter with AI that matches shipments to the right carriers. Using OptaPlanner and Google OR-Tools, the system factors in route constraints, cargo type, and capacity to reduce empty runs and manual errors. It automates load planning while keeping operations smooth and adaptive to real-time changes.

For example, a logistics firm uses the platform to consolidate nearby shipments and assign them to the most suitable carriers, reducing manual planning and avoiding underutilized trips.

We develop AI models that adjust shipping rates in real time based on changing delivery costs and demand. Powered by XGBoost and AWS SageMaker, the system accounts for variables like fuel prices, tolls, and delivery urgency to recommend optimized pricing strategies that protect margins and boost cost-efficiency.

For example, a shipping company adjusts delivery pricing dynamically based on time slots and cost inputs, allowing better control over profit margins and delivery prioritization.

Your logistics network becomes smarter with Digital Twin simulations that mirror supply chain operations. Using AnyLogic and Azure Digital Twins, you can test delivery routes, inventory shifts, and bottleneck scenarios virtually—allowing teams to make planning decisions without disrupting real-world processes.

For instance, a logistics team runs simulations to evaluate alternate routing and warehouse load balancing before implementing the most efficient flow in real-time.

We use AI to validate freight bills against actual delivery data. AppZen extracts key invoice fields like Invoice number, Line item descriptions, while AWS Textract verifies rates, delivery terms, and carrier logs—automating reconciliation and preventing overcharges due to duplicate billing, mileage errors, or misclassifications.

For instance, a freight coordinator runs automated checks on all incoming invoices and flags mismatched charges instantly—avoiding disputes and saving manual effort.

Your supply chain stays proactive with AI models that monitor weather feeds, geopolitical events, and compliance data in real time. We use IBM Watson and SAP Business AI to flag potential delays, contract violations, or customs issues before they escalate—keeping operations safe, lawful, and uninterrupted.

For example, a freight team gets early warnings on port congestion and regulatory risks, enabling quick re-routing or shipment rescheduling without last-minute disruptions or compliance breaches.

We enhance warehouse efficiency with AR-enabled smart glasses like Microsoft HoloLens and Vuzix. These devices display pick lists directly in the worker’s field of view, guiding them through optimized paths and verifying each item using visual markers—boosting speed and reducing human errors.

For example, a picker follows visual instructions to locate and confirm items hands-free, speeding up fulfillment and reducing mistakes without relying on handheld screens or paper checklists.

One click to smarter logistics

Building Precision Logistics Software

We run a lean, agile process built for speed, precision, and scale. From day one, we align with your logistics goals—whether it’s cutting delivery times, improving fill rates, or balancing demand and supply.

We start with facilitating discovery workshops, working closely with your team to understand how your logistics really work—from the moment an order comes in to when it’s delivered. We map out each step, spot the bottlenecks, and figure out what systems need to talk to each other. This helps us design software that fits your operations, makes life easier for your team, and actually solves the problems that slow you down.

Once workflows are clear, we define the core architecture and technology stack. Whether it's a WMS, FMS, or dispatch app, decisions are based on integration needs, latency, and scalability. We typically use Node.js for back-end logic and PostgreSQL for structured freight and inventory data, keeping architecture lean and scalable from day one.

Each core module—dispatch, billing, warehouse tracking—is developed independently for faster release cycles. Using Docker containers, developers isolate services like route planning or audit engines without dependency conflicts. This modular setup helps logistics teams roll out updates (e.g., tariff logic changes) without affecting ongoing shipments or system uptime.

Real-time logistics operations rely on consistent data flow. We integrate external systems—TMS, GPS trackers, ERP—using Apache Kafka for data streaming and Swagger for API standardization. This ensures clean, traceable communication between vehicles, drivers, billing platforms, and control rooms, helping operations run without manual sync errors.

To cut delays and optimize assets, predictive logic is wired into the system. We use Amazon SageMaker to forecast delivery delays and PyCaret to flag high-risk consignments based on route history and vehicle data. These models run behind dashboards, helping managers act before issues escalate into delays or penalties.

Before go-live, we test each module under live load conditions—simulating real-world dispatches, driver delays, and invoice mismatches. Using Postman for API testing and JMeter for load simulation, we validate system response, latency, and stability. Final rollouts include on-site device syncs, warehouse staff onboarding, and support handoffs.

The Tech Stack Behind Smarter Logistics

We use tools that actually solve your daily logistics headaches—real-time tracking, GPS accuracy, smooth ERP syncs.

| Fleet & Route Optimization |

|

| Warehouse & Inventory Management |

|

| Real-Time Shipment Tracking |

|

| Freight Billing & Auditing |

|

| Data Integration & Visibility |

|

| AI & Predictive Analytics |

|

| Digital Twin & Simulation |

|

| AR/VR for Warehouse Ops |

|

| Compliance & Risk Monitoring |

|

| Logistics APIs & Platforms |

|

What to expect

What to expect working with us.

We transform companies!

Codewave is an award-winning company that transforms businesses by generating ideas, building products, and accelerating growth.

Frequently asked questions

Logistics software development involves building digital tools that manage supply chain workflows, including inventory, shipments, and deliveries. These systems streamline operations, reduce manual tasks, and enhance visibility, helping logistics businesses become more responsive, data-driven, and cost-effective.

Transportation software development helps logistics businesses automate dispatching, track vehicles, optimize routes, and reduce fuel costs. It boosts delivery accuracy, minimizes delays, and offers real-time insights, making operations more efficient and aligned with customer expectations.

Logistics software typically includes live tracking, route optimization, inventory control, automated scheduling, and analytics dashboards. These features improve visibility, support faster decisions, and reduce operational costs by streamlining critical logistics and transportation processes.

Yes, logistics software development allows seamless integration with ERPs, CRMs, and IoT platforms. These integrations enable smooth data exchange, reduce duplication, and create unified workflows, helping teams operate more efficiently and make smarter decisions across the supply chain.

Industries like retail, eCommerce, manufacturing, and transportation benefit the most. Logistics software development supports warehouse automation, real-time tracking, and delivery optimization, making it essential for businesses that rely on efficient, scalable, and transparent supply chain operations.

Codewave customizes logistics software using agile methods, user research, and domain expertise. We prioritize automation, real-time tracking, and easy interfaces, building intelligent solutions that reduce inefficiencies and deliver measurable impact on logistics performance and bottom-line growth.

Codewave builds transportation software that blends intuitive UX, data intelligence, and automation. Our solutions offer smart route planning, dynamic ETAs, and real-time updates—designed to help logistics teams reduce delays, lower fuel costs, and improve customer satisfaction.

Yes, Codewave ensures seamless integration with third-party tools like ERPs, GPS trackers, and IoT platforms. Our logistics software supports open APIs and modular architecture, creating a connected environment that enables accurate, real-time logistics decision-making.

Codewave builds scalable, cloud-native logistics platforms using modular components. Our solutions adapt to growing data loads, user demands, and feature expansions—ensuring your logistics infrastructure evolves smoothly with your business without compromising speed or stability.

Yes, we develop cross-platform logistics apps for drivers, warehouse staff, and delivery agents. Codewave’s apps feature offline access, real-time updates, barcode scanning, and navigation tools—keeping your logistics workforce connected, informed, and efficient on the move.

Codewave leverages AI, IoT, cloud platforms, and data analytics for logistics software development. We use tools like AWS, Google Maps, Flutter, and React Native to build reliable, fast, and intelligent logistics platforms tailored to your business.

Codewave offers personalized, scalable solutions backed by strong UX and tech expertise. We work closely with logistics teams, deliver quickly, and focus on ROI. Our transportation software development drives efficiency, speed, and transparency across your supply chain.